Home-making made simple with an oak frame

Oakwrights’ Charlie Mills and his wife Helen are starting married life in the dream oak-frame home they created in Herefordshire.

What attracted you to the idea of creating your own family home?

Building a home felt like something you do much later in life, but when we realised it was perfectly achievable, we knew we had to do it. The opportunity to create a home unique to us and our lifestyle was very exciting. When we look at other ‘off-the-peg’ properties, we know they would not fit our lifestyle as much as a house we have designed and built ourselves.

What do you see as the attractions of building in green oak?

When you build in oak, you are embracing a traditional building method that adds significant character to a home. The ‘wow’ factor the oak frame brings, both inside and out, has meant that our décor can be simple and understated, as the oak does all the work for us. The frame adds a dimension you can never achieve with any other form of building material. I don’t think its unique and distinctive character ever loses its appeal.

Did you consider sustainability during your house design and build?

Yes, our ambition was to make it as energy-efficient and low-cost as possible to run. The house is made up of highly insulated panels that encapsulate the oak frame and are fitted to make the house air-tight, a requirement of building regulations. We installed an MVHR (Mechanical Ventilation with Heat Recovery) system which brings freshly filtered air into the house, extracting the stale air from inside, yet retaining its warmth.

How closely involved were you in designing the house?

When we purchased our plot, it came with a house design that we really liked, which was inspired by the Cottage range at Oakwrights and which already had planning permission. This is called a custom-build plot and only required a tweak to the internal layout to make sure it suited our needs and how we wanted to use the space. We also worked with the Oakwrights design team to change some subtle aspects of the external appearance.

What were the benefits of using the construction method you did?

We moved into our home within eight months of starting the groundworks. The biggest benefit of choosing an oak frame and pre-fabricated encapsulation system was that the dry shell process was completed within 11 days, from laying the base to fitting internal studwork and roof covering. The joinery and external cladding were already pre-installed to the insulated panels in the Oakwrights workshops, reducing building time significantly. In addition, because there was only one contractor looking after the oak frame and encapsulation system, all the teams, from architecture and frame design through to production could work together, so there was less opportunity for any confusion.

Would you do it again?

Yes! We were about to embark on another project within 12 months of moving in, but realised we hadn’t had time to enjoy the home we had only moved into. We do keep an eye on the property market, but once you have designed and built your own home, nothing comes close.

For 25 years, Oakwrights has been designing and building beautifully bespoke oak-frame homes, extensions and outbuildings. To discover more, telephone 01432 353353 or visit www.oakwrights.co.uk.

Exquisite houses, the beauty of Nature, and how to get the most from your life, straight to your inbox.

-

Country Life's top 10 garden stories of 2025, from Alan Titchmarsh's hardy annuals to David Beckham's Cotswolds paradise

Country Life's top 10 garden stories of 2025, from Alan Titchmarsh's hardy annuals to David Beckham's Cotswolds paradiseWe look back at the most-read architecture stories on the Country Life website in 2025.

-

Britain's most entertaining (and a little bit salacious) country house scandals

Britain's most entertaining (and a little bit salacious) country house scandals'Country houses seem to have harboured more than their fair share of scandals,' says Adrian Tinniswood, who recounts some of the most shocking.

-

Jewels of the Mediterranean: Luxury multi-generational villa holidays

Jewels of the Mediterranean: Luxury multi-generational villa holidaysThe Thinking Traveller have some of the finest villas in the Mediterranean on their books for multi-generational holidays. Here are just a few of the highlights.

-

Code8: Beauty on Burlington Arcade

Code8: Beauty on Burlington ArcadeCome along Burlington Arcade with Hetty Lintell to visit beauty gurus Code8, and try their new Day To Night Foundation.

-

The gift of growing

The gift of growingEntirely built to suit your needs, a bespoke Alitex greenhouse not only helps you nurture flowers and vegetables, but also offers a tranquil retreat from the pressures of daily life.

-

The ultimate Canadian train journey

The ultimate Canadian train journeyExperience the spectacular scenery of the Canadian Rockies onboard the luxury and top-tier service of Rocky Mountaineer.

-

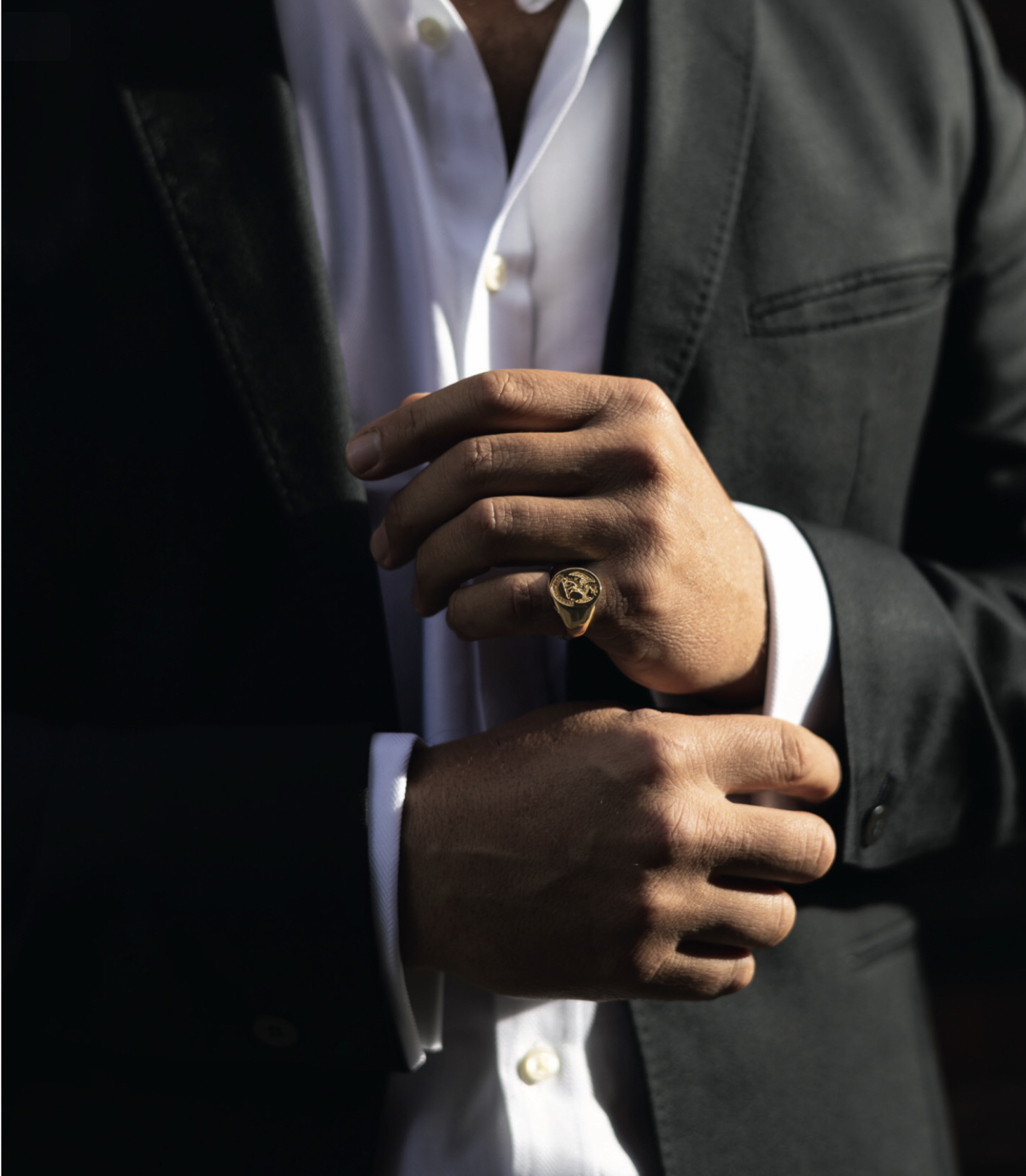

Diamonds are a man’s best friend

Diamonds are a man’s best friendMale interest in jewellery is on the rise, with gypsy and signet rings proving especially popular, according to renowned jeweller Hancocks.

-

The Art of Lighting: Four of Britain's top designers share their best tips for choosing lighting

The Art of Lighting: Four of Britain's top designers share their best tips for choosing lightingAt a recent panel discussion hosted at Vaughan’s London showroom during Focus/24, interior designers Emma Pocock and Sarah Peake, lighting designer Jo Mann of Lighthouse Designs and Richard Smith of Vaughan shared their top 10 tips on choosing lighting.

-

The beauty of bespoke: A journey with Julia Lloyd George

The beauty of bespoke: A journey with Julia Lloyd GeorgeGoing bespoke with Julia Lloyd George means getting not just a piece of jewellery, but a lifelong treasure.

-

Hancocks: Sparkle of genius

Hancocks: Sparkle of geniusHistoric jewellery firm Hancocks, now in its new St James’s home, specialises in old-cut diamonds pieces that gleam and turn heads even in low light.