Curious Questions: Is there a 'right' way up to use aluminium foil?

As we prepare to embark upon the season of wrapping leftover foodstuffs, Martin Fone answers a question that's been bugging us for years: is it dull side up and shiny side down, or the other way around?

Aluminium — or aluminum, if you're ready this from the other side of the Atlantic — is the third most abundant element on the earth’s crust, after oxygen and silicon; and the second most used metal, after iron. Yet, curiously, it is one of the more recently discovered metals. Chemically bound to other ores, particularly bauxite, it is not found in its purest form naturally. However, alums, hydrated salts containing aluminium and sulphur, have been used for almost five thousand years as a mordant to fix dyes, to preserve leathers, for dressing wounds, and as an early form of deodorant.

When, in 1750, Andreas Margraff developed an alum without sulphur, scientists began to speculate whether there was a previously undiscovered base metal within it, tentatively named ‘alumine’ by Guyton de Morveau in 1761. These suspicions were not confirmed until 1807 when Humphrey Davy used his newly developed electrolysis process to try to isolate aluminium from its mineral source.

Although he failed in his objective, he wrote in a paper published in the Royal Society’s Philosphical Transactions the following year that ‘had I been so fortunate as to have obtained more certain evidences on this subject, and to have procured the metallic substances I was in search of, I should have proposed for them the names of silicium, alumium, zirconium, and glucium’.

By the time he penned his Elements of Chemical Philosophy in 1812 Davy was calling it aluminum, a name that the Americans use to this day. The suffix -um rather than the more pleasing -ium offended the classically trained sensibilities of the British scientific community, who coined ‘aluminium’, a term first appearing in the Royal Society’s review of Davy’s experiments in 1811 and used this side of the Atlantic ever since.

Davy’s dream of producing a sample of elemental aluminium was realised in 1825 by Hans Christian Ørsted, although it was too small to conduct even the most basic analysis on and his methodology was difficult to replicate. It took until 1845 for Fredrich Wőhler to produce a ‘grey metallic powder…[with] small tin-white globules [of aluminium], some as large as pins’ heads’, by heating potassium and aluminium chloride together.

By 1854 Henri Deville, a French chemist, had developed a chemical process for extracting aluminium from bauxite, an expensive process which yielded small quantities of metal, leading him to lament that ‘every clay bank is a mine of aluminium, and the metal is as costly as silver’. It was even more expensive than that, its use reserved for ostentatious displays such as the aluminium breastplate, spoons, and baby’s rattle commissioned by Napoleon III, and the 100-ounce aluminium pyramid at the tip of the Washington Monument.

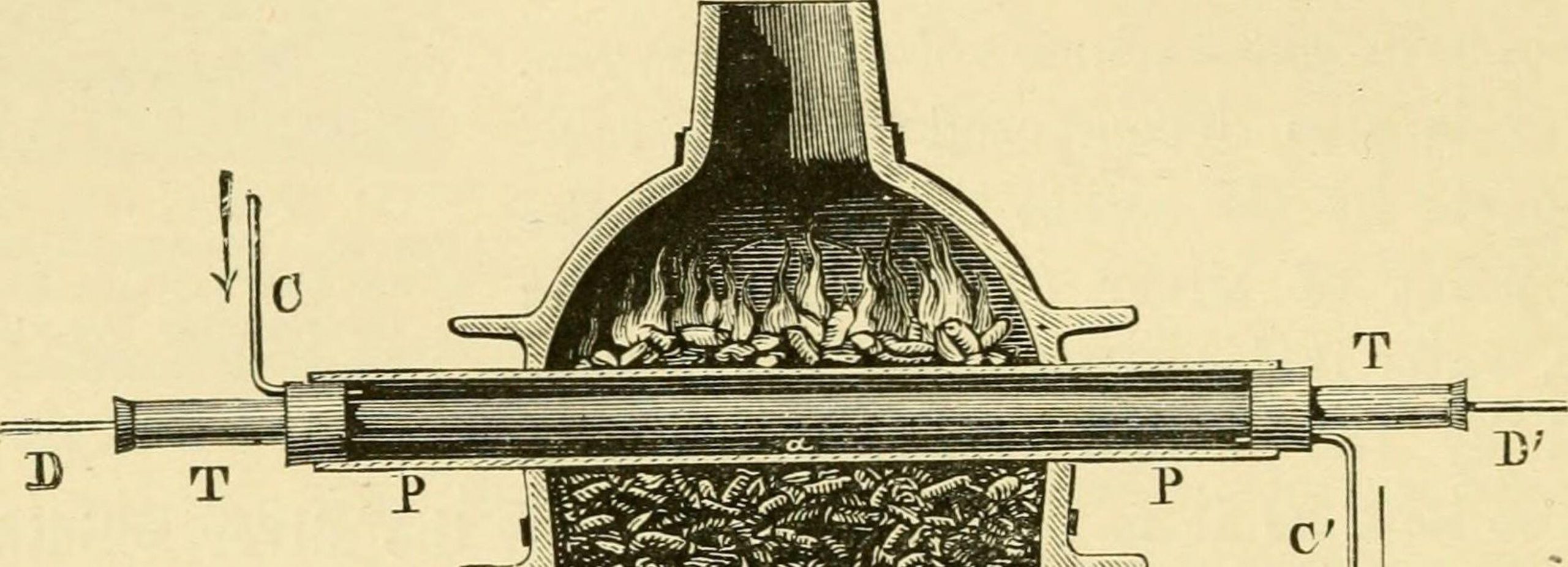

Siblings Charles and Julia Hall, intrigued by Deville’s methodology, thought that harnessing the power of the industrial-sized batteries that were now available through electrolysis would produce larger quantities of aluminium more cheaply than Deville’s chemical separation method. They were right, Charles producing marble-sized pellets of aluminium on February 23, 1886, by running an electric current through a solution of aluminium oxide mixed with melted cryolite would ease the process of extracting aluminium and bring down its cost.

Sign up for the Country Life Newsletter

Exquisite houses, the beauty of Nature, and how to get the most from your life, straight to your inbox.

The date was significant because in France, Paul Héroult, using the same process to produce aluminium, was quicker off the mark in applying for a patent. When Hall applied for his patent on July 9, 1896, he was sued by Héroult for infringement of the patent granted him on April 23, 1886. Thanks in part to Julia’s testimony, Hall demonstrated to the court’s satisfaction that he had a prior claim.

With a patented process that produced aluminium cheaply and in large quantities, Hall established the Pittsburgh Aluminum Company, later to become Alcoa, which by 1890 was daily producing 250 kilogrammes of the metal. He bequeathed to Alcoa on his death in December 1914 what they regard as their crown jewels, a chest holding the small aluminium pellets produced from his first successful experiment.

The possibilities offered by this lighter, more flexible metal were quickly recognised by inventors and design pioneers. Le Migron, commissioned by Alfred Nobel in 1891, was the first passenger ship with an aluminium hull, while the Hartford Railway Company produced lightweight railway carriages with aluminium seats in 1894. Karl Benz exhibited the first sports car with an aluminium body in Berlin in 1899 and the Wright brothers finally got off the ground with an engine containing aluminium parts.

Manufacturers of household goods also caught the aluminium bug. In 1893 the first mass-produced aluminium kettles were marketed, soon to be followed by frying pans and saucepans, which were lighter and warmed up and cooled down more quickly than their copper and cast-iron predecessors. Aluminium was also seen as a possible alternative to tin foil which, although it had been used since the 18th century to wrap food in while cooking, was expensive to manufacture, rather stiff, and left a bitter, metallic taste.

Robert Victor Neher’s invention of a continuous rolling process to produce thin strips of aluminium foil encouraged him to open the world’s first aluminium rolling plant in the Swiss town of Kreuzlingen in 1910. Bern-based chocolate manufacturer, Tobler, was an early adopter, wrapping their confectionary, including the distinctive triangular Toblerone, in aluminium foil from 1911. Maggi followed suit, using it the next year to package soups and stock cubes.

Aluminium foil soon demonstrated its superiority. It was a much more effective conductor of heat and electricity than tin foil, able to withstand very high temperatures, thus preventing foodstuffs from drying out in the oven. Once the food had been cooked, foil extended its life by offering an effective barrier against light, oxygen, and moisture.

Outside the kitchen it is used by pharmaceutical companies to package drugs and by food manufacturers to produce aseptic packaging which allows perishable goods to be stored without refrigeration. By the mid-20th century aluminium foil, of which Britain is one the largest consumers in the world, had almost completely replaced tin, although, confusingly, it is sometimes still called tin foil.

One of aluminium foil’s most distinctive visual features is a consequence of its manufacturing process. To meet the standards of ISO 7271:2011, the sheets must be between 0.006 and 0.2 millimetres thick and are milled in layers, a process which involves the application of heat and tension to stretch the foil to the required thickness. As a single strip is likely to break during the process, two layers are milled together and then separated.

Where the sides of the two layers have been in contact with each other they develop a matt or dull finish while the outer layers retain a gloss or shiny appearance. However, the performance of the foil is the same, irrespective of which side forms the outside of the wrapping. It seems it is simply a question of aesthetics. When it comes to non-stick foil, though, only one side is treated with the non-stick coating and food must be placed on the side marked ‘non-stick’.

In future, I will wrap my food in foil to reflect my disposition; shiny side out if I am happy and dull side out if I am down. You never know, it might catch on.

After graduating in Classics from Trinity College Cambridge and a 38 year career in the financial services sector in the City of London, Martin Fone started blogging and writing on a freelance basis as he slipped into retirement. He has developed a fearless passion for investigating the quirks and oddities of life and discovering the answers to questions most of us never even think to ask. A voracious reader, a keen but distinctly amateur gardener, and a gin enthusiast, Martin lives with his wife in Surrey. He has written five books, the latest of which is More Curious Questions.

-

Designer's Room: A solid oak French kitchen that's been cleverly engineered to last

Designer's Room: A solid oak French kitchen that's been cleverly engineered to lastKitchen and joinery specialist Artichoke had several clever tricks to deal with the fact that natural wood expands and contracts.

By Amelia Thorpe

-

Chocolate eggs, bunnies and the Resurrection: Country Life Quiz of the Day, April 18, 2025

Chocolate eggs, bunnies and the Resurrection: Country Life Quiz of the Day, April 18, 2025Friday's quiz is an Easter special.

By James Fisher

-

Curious Questions: What is the greatest April Fool's prank ever played?

Curious Questions: What is the greatest April Fool's prank ever played?As April 1 looms, Martin Fone tells the tale of one of the finest stunts ever pulled off.

By Martin Fone

-

Curious questions: Why do we use Seville oranges to make marmalade?

Curious questions: Why do we use Seville oranges to make marmalade?Why do we use Seville oranges to make marmalade when there are more than 400 other varieties available worldwide? And do they really make the best preserve? Jane Wheatley investigates.

By Jane Wheatley

-

Mince pies really did once contain meat — and this Victorian recipe will convince you that they should to this day

Mince pies really did once contain meat — and this Victorian recipe will convince you that they should to this dayOnce packed with meat, such as ox tongue and mutton, alongside dried and candied fruit and extravagant spices, the mince pie is not what it once was — and food historian Neil Buttery says that's made them worse.

By Neil Buttery

-

Curious Questions: Margarine used to be pink — but why?

Curious Questions: Margarine used to be pink — but why?Margarine has been a staple of our breakfast tables for over a century, but it hasn't always had a smooth ride — particularly from the dairy industry, who managed to impose a most bizarre sanction on their easily-spreadable, industrially mass-produced rival. Martin Fone explains.

By Martin Fone

-

Curious Questions: Wine has been made in Britain for over 1,000 years — so why have we only just turned it into an industry?

Curious Questions: Wine has been made in Britain for over 1,000 years — so why have we only just turned it into an industry?With the UK wine industry booming, Martin Fone takes a look at its history.

By Martin Fone

-

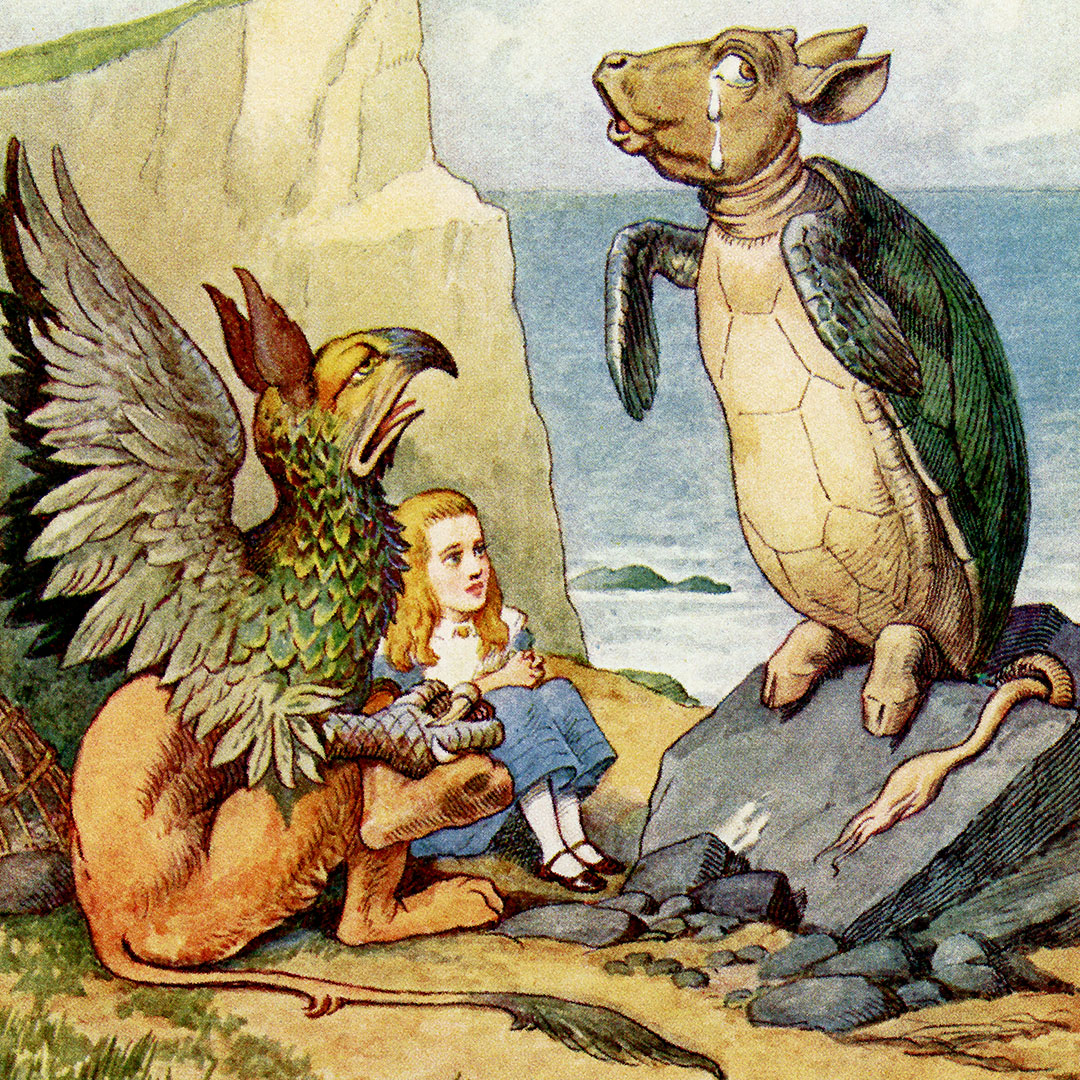

Curious Questions: What is mock turtle soup? And did it come before or after 'Alice in Wonderland'?

Curious Questions: What is mock turtle soup? And did it come before or after 'Alice in Wonderland'?Martin Fone delves into the curious tale of an iconic Victorian delicacy: mock turtle soup.

By Martin Fone

-

A game of two halves — how the sandwich went from humble fare to a country-wide lunchtime obsession

A game of two halves — how the sandwich went from humble fare to a country-wide lunchtime obsessionWhat started life as a way to eat and play cards at the same time (so the story goes) is now the lunch of choice for the working world.

By Emma Hughes

-

Where to find the world's best club sandwich — and the story of this triple-layered paean to poolside delight

Where to find the world's best club sandwich — and the story of this triple-layered paean to poolside delightThe club sandwich, arguably the most famous of all sarnies, is a poolside staple, but its origins are tricky to trace, says Tom Parker Bowles.

By Tom Parker-Bowles