The traditional Brick-Maker who supplies Hampton Court: 'It’s like kneading dough'

There is only one company left in Britain still producing hand-made bricks – and their customers include the likes of Hampton Court. Tessa Waugh spoke to the gentlemen of H. G. Matthews.

Family-run H. G. Matthews is the only company in Britain still producing traditional, handmade bricks in a wood-fired kiln. Based in the Chiltern Hills, the historic centre of brickmaking, the company uses clay from its own farmland to produce about 12,000 machine-made facing bricks and 8,000 handmade facing bricks a day, in a variety of metric or imperial sizes.

In addition, some bricks are custom-made for historic buildings, such as Hampton Court Palace and, most recently, chimney and parapet repairs at The Vyne in Hampshire.

‘We use iron-rich clay, which can produce a wide spectrum of colours – rich reds, muted oranges, mauves and deep browns, depending on the temperature and positioning within the kiln,’ explains craftsman brickmaker Andrew Hales, whose evocative descriptions make the bricks sound like objects of beauty.

The method of making them has remained unchanged since the company was founded in 1923, with the clay going through several processes before it arrives on the brickmaker’s bench.

The forming of the brick takes a matter of seconds, as so ably demonstrated by John Lisley in the photograph below.

‘It’s like kneading dough,’ explains Mr Hales.

‘The maker throws a clot of clay onto the sanded bench, then swiftly rolls and turns it before picking it up between his palms, throwing it downwards into the sanded mould and removing the excess with a wooden strike.’

Sign up for the Country Life Newsletter

Exquisite houses, the beauty of Nature, and how to get the most from your life, straight to your inbox.

Find out more at the company’s website, www.hgmatthews.com, or see more British craftsmen at www.heritagecrafts.org.uk.

The gold stamper: ‘The younger generation is very appreciative of artisan work – they’re the ones driving the trend’

This week's Living National Treasure is John Timms, the man who leads the team that stamps gold lettering into thousands

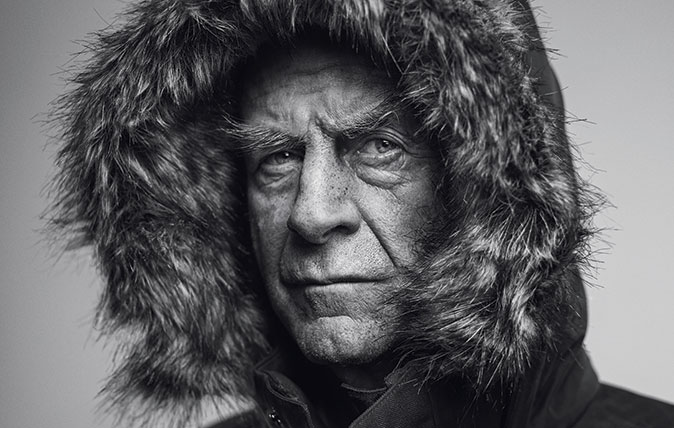

Credit: Sir Ranulph Fiennes (Getty)

Ranulph Fiennes: 'Commuting up and down the motorway is more dangerous than a trip to the Arctic'

Explorer, adventurer and national treasure, Sir Ranulph Fiennes has travelled to the ends of the earth and raised millions for

Credit: Living National Treasure: The Glassblower - ©Country Life/Richard Cannon

The Glassblower: 'When something goes wrong you can't fix it – you just sling in into the bosh bucket and start again'

Ian Shearman's team of glassblowers are still making glass using a technique that's 2,000 years old. Mary Miers found out

Country Life is unlike any other magazine: the only glossy weekly on the newsstand and the only magazine that has been guest-edited by HRH The King not once, but twice. It is a celebration of modern rural life and all its diverse joys and pleasures — that was first published in Queen Victoria's Diamond Jubilee year. Our eclectic mixture of witty and informative content — from the most up-to-date property news and commentary and a coveted glimpse inside some of the UK's best houses and gardens, to gardening, the arts and interior design, written by experts in their field — still cannot be found in print or online, anywhere else.

-

Everything you need to know about private jet travel and 10 rules to fly by

Everything you need to know about private jet travel and 10 rules to fly byDespite the monetary and environmental cost, the UK can now claim to be the private jet capital of Europe.

By Simon Mills

-

'I'd willingly give a year of my life for a fortnight there': The green dream that is the garden of Derreen

'I'd willingly give a year of my life for a fortnight there': The green dream that is the garden of DerreenExotic woods, labyrinths of narrow, mossy paths and thousands of tree ferns make this an internationally important garden, writes Charles Quest-Ritson. Photographs by Jonathan Hession.

By Charles Quest-Ritson

-

The lock-gate maker: ‘Maintaining them can be a bit like painting the Forth Bridge’

The lock-gate maker: ‘Maintaining them can be a bit like painting the Forth Bridge’Tessa Waugh meets Steve Brunt, a workshop supervisor for the Canal and River Trust, which is dedicated to protecting and maintaining more than 2,000 miles of waterways in England and Wales.

By Country Life

-

The Stonemason: 'Working on a cathedral is the pinnacle of architectural stone-masonry'

The Stonemason: 'Working on a cathedral is the pinnacle of architectural stone-masonry'A team of stonemasons is hard at work restoring Canterbury's magnificent cathedral, employing techniques that have been used since the dawn of civilisation. They spoke to Tessa Waugh.

By Country Life