Powered by the wind since 1887: The past, present and future of Britain's wind turbines

Wind turbines are becoming a familiar feature of the landscape. John Goodall looks at their operation, form and future through the example of Whitelee Windfarm in East Renfrewshire, the largest onshore wind farm in the UK.

Wind turbines have long been objects of controversy. The erection of large, prominent and moving manmade structures in the landscape has seemed shocking to some. To make matters worse, wind farms have necessarily been erected in remote areas loved for their wild beauty. Attitudes towards them, however, have undoubtedly softened in the past few years. A widespread acknowledgement of the reality of climate change and, more recently, the massive spike in energy prices caused by the war in Ukraine have done a great deal to shift attitudes. Certainly, if we are to enjoy affordable power and reduce our carbon emissions, wind is clearly a hugely important future source of clean energy. Whether we love or loathe them, therefore, they are a fixture for the foreseeable future.

There is no better way to learn about wind farms than by visiting the largest on-shore example in the UK. Whitelee Wind Farm, built by Scottish Power between 2007 and 2009, comprises 215 individual turbines set out across 32 square miles of peat moor in East Renfrewshire, East Ayrshire and South Lanarkshire. Although Scotland constitutes only 1% of the European landmass, it receives a disproportionately high quantity of the area’s wind. This makes it particularly well suited to wind-generated power; that’s in contrast to much of England, which has less wind and more sun, making solar panels a better source of renewable energy. Scotland’s wind may also explain why the first turbine to generate electricity was set up by a Glasgow engineer, Prof James Blyth, to power his holiday home at Marykirk in 1887.

The placement of modern turbines relates not only to wind, but the inherited infrastructure of power supply. Its foundations were laid in the middle decades of the 20th century with the establishment of the National Grid and the post-war decisions to supply the bulk of the power on it with a network of power stations variously fuelled by coal, nuclear fuel and gas. The consumption of power is relatively predictable, but even today gas, in particular, remains important as the only reliable means of creating a rapid supply at moments of peak usage. The grid was conceived as a transmission system that could carry high-voltage electricity — which travels with much less wastage — by pylon to the areas where it was needed. A low-voltage network of cables and poles then distributed the power locally.

Precisely because coal and gas remained cheap, it was not until the 1970s that Britain, Denmark and Germany began to develop prototype wind turbines. It was a further 20 years before the commercial potential of this technology began to be explored in Britain. Scottish Power bought its first wind farm at Carlingcross in Cornwall in 1992 and built its first one in 1995 at Hagshaw Hill, Lanarkshire. At the time, the construction of turbines was relatively expensive, with a poorly developed supply chain of parts. Financial incentives from the Government for renewable energy, therefore, played an important early role in getting this technology off the ground in the UK.

Whitelee was first identified as a suitable site for wind generation in 2001. Not only was the moor exposed — and very windy, even by Scottish standards — but conveniently situated with easy access to the existing transmission grid. It was also close to several centres of population, including Glasgow, about 10 miles to the north. It’s a striking statistic that the entire area of the wind farm is about half that of the city itself. As well as overcoming public opposition to the scheme and securing planning permission, Scottish Power had to confront a practical problem with developing the site. Wind farms cause interference or ‘clutter’ on radar, so new radar facilities had to be created before work could begin.

In advance of construction, it was necessary to determine the placement of turbines on the moor, which are organised in groups or ‘arrays’ of six to eight with linked cables. The individual turbines need to be positioned in the landscape so as to take maximum advantage of the prevailing wind — which, at Whitelee, is from the north-west — without shadowing each other. One way of doing this is to erect anemometers — devices that measure wind speed and direction — across the site on the proposed position of turbines and test their results over a period of time.

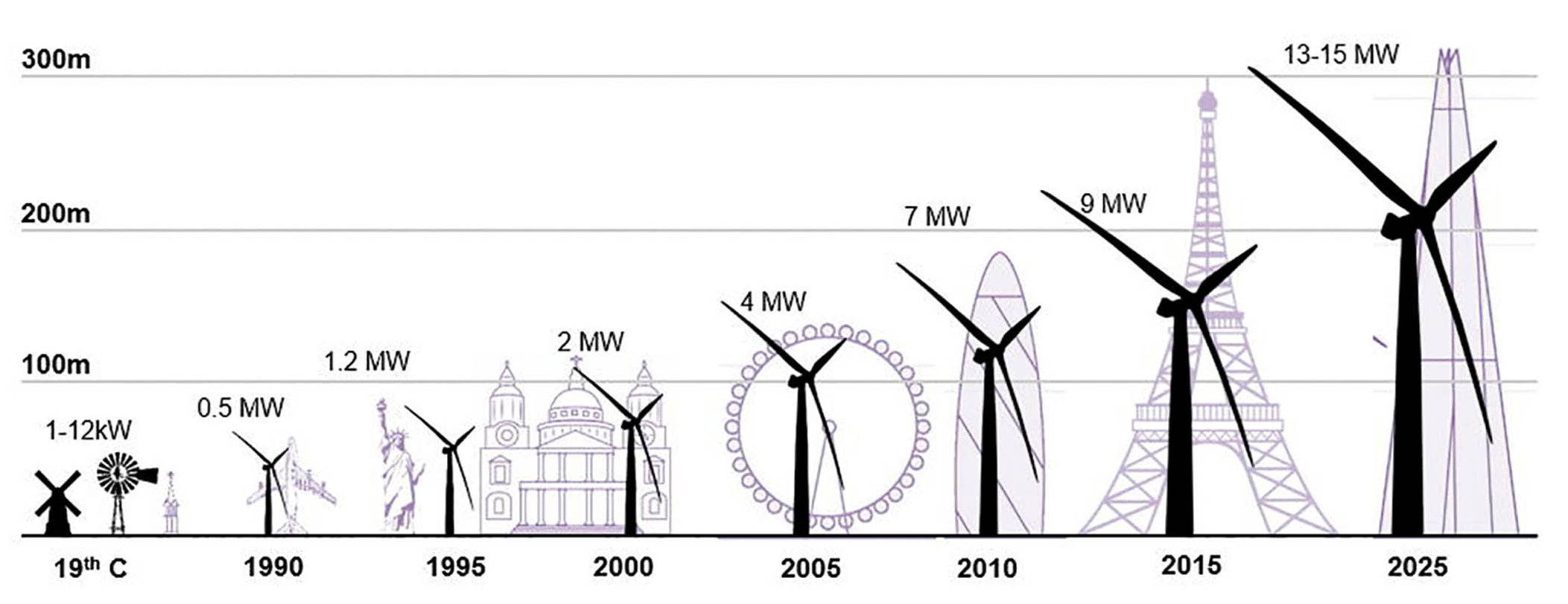

Evolution of wind-turbine heights and output

Another important consideration was the effect of the turbines on birds. Wind farms should not be erected on regular migration routes and, in some cases, the needs of particular species have to be taken into account. At another wind farm, Beinn An Tuirc on Mull of Kintyre, for example, Scottish Power recently liaised with the RSPB to create an alternative habitat for golden eagles to attract them away from the turbines. In the case of Whitelee, a substantial area of the wind farm is formally designated as a Habitat Management Area and supports a wide diversity of wildlife.

Sign up for the Country Life Newsletter

Exquisite houses, the beauty of Nature, and how to get the most from your life, straight to your inbox.

It should be said in this regard that one of the great advantages of turbines is that, in most respects, they do not interfere with existing habitats or land use. That’s in contrast, for example, with solar panels, which in rural settings often cover fields and necessarily change land usage. In the case of Whitelee, parts of the site are otherwise owned by the Forestry and Land Scotland, Scottish Water or worked as farmland.

When the construction here finally began in 2007, work was extraordinarily rapid. A network of roads extending about 80 miles was laid over the top of the peat moor, using earth and rock extracted for the concrete foundations on which the individual turbines sit. There are three types of turbine across the site, but the principal components of all are the same: a tower, a nacelle and a rotor with blades. The tower is essentially a tall tube. It usually comes in sections and, in the most recent designs, incorporates a service lift. On top of this is the nacelle, a casing that can revolve freely on the tower. An anemometer turns the nacelle so that the attached rotor, with its three long blades, can face the wind and operate with the greatest efficiency.

The nacelle contains the generator that is driven by the rotor blades. Connecting the two is a gear system that increases the speed at which the generator mechanism spins, so producing more electricity. From an engineering point of view, the number and design of the rotor blades is crucially important. There are three — rather than two or four — blades and they operate in the face of winds between 6mph and 56mph. During sustained gusts over the latter wind speed, the gears in the nacelle will cause the rotor and generator to disconnect and prevent damage to the turbine. Depending on the force of the wind, the rotor will turn between one and 16 times in a minute, with the tip of the largest blades travelling at up to 190mph.

The components of the most numerous turbine type at Whitelee were manufactured by Siemens in Denmark and were shipped to Glasgow for assembly on site. Each of these has a blade diameter of 305ft (93m) and stands 361ft (110m) high. Incredibly, that’s just short of the 364ft dome of St Paul’s Cathedral in London. With the help of a crane, the entire process of assembling a single turbine of this type took a team of 20 men two days. In addition to the 140 Siemens turbines there are six Alstom turbines of about the same size and a further 69 Alstom turbines about 460ft high (140m). All are painted off white, a colour derived from the colour of the clouds against which turbines are usually to be seen outlined. Work on the whole wind farm was completed in only two years.

The turbines produce electricity at 690 volts and each array is connected to a transformer (camouflaged in green) that increases its voltage in order to allow it to travel with less wastage. From the transformer, at 33,000 volts, it passes to a primary substation, where it joins the grid at either 275,000 volts or 400,000 volts. A reverse process reduces the voltage and allows the electricity to be locally distributed at the point of need. The actual quantity of electricity produced depends on the wind, but a single revolution of the rotor produces sufficient electricity to charge about 300 mobile phones. Each Siemens turbine has a maximum output of 2.3 megawatts, roughly enough to power 1,000 homes, and over the past three months the average daily output of the wind farm as a whole has been 4,475 megawatt hours.

All this, of course, is a small fraction of national usage. Daily demand in the UK is presently somewhere between 34 and 45 giga-watts and that of Scotland alone is between three to five gigawatts. Despite energy-saving technology, that demand is likely to grow exponentially in the years ahead as people turn to electric power for more of their energy needs. At present, for example, 87% of homes in the country are heated by gas, a situation that may change in the near future. In all its forms, meanwhile, transport is increasingly taking advantage of electricity rather than using fossil fuels directly.

Wind as a clean and plentiful supply of power clearly has an important role to play in meeting this growing demand. In part, this is a consequence of continual improvements in the technology available with a clear trend towards fewer and larger turbines. These promise to make the generation of electricity by wind ever more efficient and cheaper. It’s one indication of the huge changes that have taken place in the past 40 years that whereas the first wind farms had a capacity of 750 kilowatts, the single largest turbines can today generate 20 megawatts, enough to power 20,000 houses. As old turbines age and are replaced, existing wind farms will consequently shrink in area and grow in height.

Another important change is the capacity to build offshore wind farms, where the wind is yet more plentiful and reliable. Hitherto, it has only been possible to construct them in relatively shallow areas of the sea around the English coast, but it is now feasible to anchor turbines off the much deeper Scottish coastline. These structures, which borrow from the experience of managing oil rigs, can be yet bigger still — and more powerful — than their counterparts onshore. They are also less immediately visible to those who will benefit.

Meanwhile, the manufacture of parts is growing more efficient, making construction quicker and cheaper. Building an offshore wind farm might now take two years and one onshore half that time. Only a solar farm, which might take a month, can be erected more quickly. By degrees, and with a combination of wind, solar, hydroelectricity and tidal power (diversity of sources is vital for system resilience), the fossil fuels that once powered the bulk of our national energy supply could be largely displaced. Indeed, huge strides have been taken in that direction. Today, on average, 97% of Scotland’s electricity is being produced from renewable sources. In England, that figure is about 50%, but rising all the time.

One of the surprises of Whitelee was that this huge piece of infrastructure is now an attraction. Scotland’s right to roam meant the site’s service roads were publicly accessible and the area was consciously developed as a public amenity with walks and rides. These proved unexpectedly popular; a visitor centre and café have been erected as an afterthought.

It’s not hard to see what draws people here. There is something compelling about the ranks of these massive machines deployed in restless, but stationary rows across such a huge landscape; so, too, the scale of the turbines close up and the swish of their sweeping blades. When rain falls, it rattles on the metal surfaces and in sunshine there is the ubiquitous sound of larks on the wing.

This is industrial architecture that we must accommodate by necessity, but which we might come to love with acquaintance. Who knows, perhaps, like cooling towers, in the future we may even come to regret its disappearance.

John spent his childhood in Kenya, Germany, India and Yorkshire before joining Country Life in 2007, via the University of Durham. Known for his irrepressible love of castles and the Frozen soundtrack, and a laugh that lights up the lives of those around him, John also moonlights as a walking encyclopedia and is the author of several books.

-

A woolly mammoth skeleton is among the curiosities for sale to save fire-ravaged Parnham Park

A woolly mammoth skeleton is among the curiosities for sale to save fire-ravaged Parnham ParkThe auction of the owner James Perkins' collection, hosted by Dreweatts, tomorrow (May 13), will be used to fund renovation works at Parnham Park in Dorset.

-

The ‘utterly unique’ skincare brand that’s used in the ‘world’s best hotel’ spa

The ‘utterly unique’ skincare brand that’s used in the ‘world’s best hotel’ spaThe Seed to Skin brand was the byproduct of one woman’s length fertility journey — it’s so good that today it’s used in a hotel voted the ‘world’s best’.